MenuClose

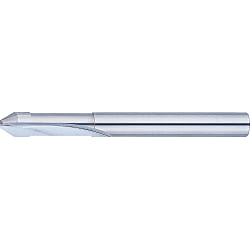

Carbide Straight Blade Corner Angle End Mill, 2-Flute, Neck Relief Type

Carbide Straight Blade Corner Angle End Mill, 2-Flute, Neck Relief Type

Part Number

Configure to get your Part Number

| Part Number |

|---|

| BSZCAEM4-[3.01-4/0.01]-[5-85/1]-[0-59/1]-[0.1-1.9/0.01]-[3-10/0.5]-[5-12/0.5]-[F,T] |

| BSZCAEM6-[3.01-6/0.01]-[5-85/1]-[0-59/1]-[0.1-2.9/0.01]-[3-19/0.5]-[5-20/0.5]-[F,T] |

| BSZCAEM8-[4.01-8/0.01]-[5-85/1]-[0-59/1]-[0.1-3.9/0.01]-[3-23/0.5]-[5-20/0.5]-[F,T] |

| BSZCAEM10-[6.01-10/0.01]-[5-85/1]-[0-59/1]-[0.1-4.9/0.01]-[3-30/0.5]-[5-20/0.5]-[F,T] |

| BSZCAEM12-[8.01-12/0.01]-[5-85/1]-[0-59/1]-[0.1-5.9/0.01]-[3-31/0.5]-[5-20/0.5]-[F,T] |

| BSZCAEM16-[10.01-16/0.01]-[5-85/1]-[0-59/1]-[0.1-7.9/0.01]-[3-43/0.5]-[5-20/0.5]-[F,T] |

| LS-BSZCAEM4-[3.01-4/0.01]-[5-85/1]-[0-59/1]-[0.1-1.9/0.01]-[3-10/0.5]-[5-12/0.5]-[F,T] |

| LS-BSZCAEM6-[3.01-6/0.01]-[5-85/1]-[0-59/1]-[0.1-2.9/0.01]-[3-19/0.5]-[5-20/0.5]-[F,T] |

| LS-BSZCAEM8-[4.01-8/0.01]-[5-85/1]-[0-59/1]-[0.1-3.9/0.01]-[3-23/0.5]-[5-20/0.5]-[F,T] |

| LS-BSZCAEM10-[6.01-10/0.01]-[5-85/1]-[0-59/1]-[0.1-4.9/0.01]-[3-30/0.5]-[5-20/0.5]-[F,T] |

| LS-BSZCAEM12-[8.01-12/0.01]-[5-85/1]-[0-59/1]-[0.1-5.9/0.01]-[3-31/0.5]-[5-20/0.5]-[F,T] |

| LS-SZCAEM4-[3.01-4/0.01]-[5-85/1]-[0-59/1]-[0.1-1.9/0.01]-[3-10/0.5]-[5-12/0.5]-[F,T] |

| LS-SZCAEM6-[3.01-6/0.01]-[5-85/1]-[0-59/1]-[0.1-2.9/0.01]-[3-19/0.5]-[5-20/0.5]-[F,T] |

| LS-SZCAEM8-[4.01-8/0.01]-[5-85/1]-[0-59/1]-[0.1-3.9/0.01]-[3-23/0.5]-[5-20/0.5]-[F,T] |

| LS-SZCAEM10-[6.01-10/0.01]-[5-85/1]-[0-59/1]-[0.1-4.9/0.01]-[3-30/0.5]-[5-20/0.5]-[F,T] |

| LS-SZCAEM12-[8.01-12/0.01]-[5-85/1]-[0-59/1]-[0.1-5.9/0.01]-[3-31/0.5]-[5-20/0.5]-[F,T] |

| SZCAEM4-[3.01-4/0.01]-[5-85/1]-[0-59/1]-[0.1-1.9/0.01]-[3-10/0.5]-[5-12/0.5]-[F,T] |

| SZCAEM6-[3.01-6/0.01]-[5-85/1]-[0-59/1]-[0.1-2.9/0.01]-[3-19/0.5]-[5-20/0.5]-[F,T] |

| SZCAEM8-[4.01-8/0.01]-[5-85/1]-[0-59/1]-[0.1-3.9/0.01]-[3-23/0.5]-[5-20/0.5]-[F,T] |

| SZCAEM10-[6.01-10/0.01]-[5-85/1]-[0-59/1]-[0.1-4.9/0.01]-[3-30/0.5]-[5-20/0.5]-[F,T] |

| SZCAEM12-[8.01-12/0.01]-[5-85/1]-[0-59/1]-[0.1-5.9/0.01]-[3-31/0.5]-[5-20/0.5]-[F,T] |

| SZCAEM16-[10.01-16/0.01]-[5-85/1]-[0-59/1]-[0.1-7.9/0.01]-[3-43/0.5]-[5-20/0.5]-[F,T] |

Loading...

Specification Table

| Model Number | Blade Diameter D 0.01mm Unit Specification | Corner Angle (Single Corner) θ °−min 1' Unit Specification | Angle Width D1 0.01mm Unit Specification | Blade Length* ℓ 0.5 mm Unit Specification | Neck Length* ℓ1 1mm Unit Specification | End Cutting Edge Shape (Selection) | *Under-neck Length Specified Range ℓ2 | Overall Length L | ||

| Shank diameter d | ||||||||||

| BSZCAEM | LS−BSZCAEM | |||||||||

| BSZCAEM LS−BSZCAEM (Long Shank) | 4 | 3.01 to 4.00 | 5°0' to 85°0' | 0.10 ≤ D1 ≤ (D−0.2)/2 | 3.0 to 10.0 | 5 ≤ ℓ1 ≤ 20 | T (Indented Center) F (Flat) | ℓ+ℓ1 ≤ 15 | 50 | 80 |

| 6 | 3.01 to 6.00 | 3.0 to 19.0 | ℓ+ℓ1 ≤ 24 | 60 | 90 | |||||

| 8 | 4.01 to 8.00 | 3.0 to 23.0 | ℓ+ℓ1 ≤ 28 | 60 | 90 | |||||

| 10 | 6.01 to 10.00 | 3.0 to 30.0 | ℓ+ℓ1 ≤ 35 | 80 | 120 | |||||

| 12 | 8.01 to 12.00 | 3.0 to 31.0 | ℓ+ℓ1 ≤ 36 | 80 | 120 | |||||

| 16 | 10.01 to 16.00 | 3.0 to 43.0 | ℓ+ℓ1 ≤ 48 | 100 | − | |||||

| Model Number | Blade Diameter D 0.01mm Unit Specification | Corner Angle (Single Corner) θ °−min 1' Unit Specification | Angle Width D1 0.01mm Unit Specification | Blade Length* ℓ 0.5 mm Unit Specification | Neck Length* ℓ1 1mm Unit Specification | End Cutting Edge Shape (Selection) | *Under-neck Length Specified Range ℓ2 | Overall Length L | ||

| Shank diameter d | ||||||||||

| SZCAEM | LS−SZCAEM | |||||||||

| SZCAEM LS−SZCAEM (Long Shank) | 4 | 3.01 to 4.00 | 5°0' to 85°0' | 0.10 ≤ D ≤ (D − 0.2)/2 | 3.0 to 10.0 | 5 ≤ ℓ1 ≤ 20 | T (Indented Center) F (Flat) | ℓ+ℓ1 ≤ 15 | 50 | 80 |

| 6 | 3.01 to 6.00 | 3.0 to 19.0 | ℓ+ℓ1 ≤ 24 | 60 | 90 | |||||

| 8 | 4.01 to 8.00 | 3.0 to 23.0 | ℓ+ℓ1 ≤ 28 | 60 | 90 | |||||

| 10 | 6.01 to 10.00 | 3.0 to 30.0 | ℓ+ℓ1 ≤ 35 | 80 | 120 | |||||

| 12 | 8.01 to 12.00 | 3.0 to 31.0 | ℓ+ℓ1 ≤ 36 | 80 | 120 | |||||

| 16 | 10.01 to 16.00 | 3.0 to 43.0 | ℓ+ℓ1 ≤ 48 | 100 | − | |||||

*The combined size of the blade length (ℓ) and neck length (ℓ1) are within the above-mentioned under-neck length specification range.

Click here for the cutting conditions

Basic Information

| Material | Ultrafine Particulate Carbide |

|---|

-

Shank Diameter d(mm)

- 4

- 6

- 8

- 10

- 12

- 16

-

Overall Length L(mm)

-

Processing Application

- Boss Hole Drilling

- Flank / Groove Processing

-

Corner Angle (Single Angle)(θ)(°)

-

Corner Angle (Single Angle)(θ)(′)

-

Angular Width (D1)(mm)

-

Bottom Blade Shape

- F (Flat)

- T (Center Dented)

-

Flute Diameter (D)(mm)

-

Flute Length (ℓ)(mm)

-

Neck Length (ℓ1)(mm)

-

type

- BSZCAEM

- LS-BSZCAEM

- LS-SZCAEM

- SZCAEM

Days to Ship

-

- All

- 5 Days or Less

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Additional Products in this Category

- Carbide Straight Blade Radius End Mill, 2-Flute, Neck Relief Model

- Carbide Straight Blade Corner Angle End Mill, 2-Flute, Tip Diameter Designation Type

- Carbide Straight Blade Corner Angle End Mill, 2-Flute, Rounded Corner Type

- Carbide Straight Blade Corner Angle End Mill, 2-Flute, Back Tapered Type

- Carbide Straight Blade Corner Angle End Mill, 2-Flute, Rounded Shoulder Type

- Carbide Straight Blade Corner Angle End Mill, 2-Flute, Rounded Inner Type

- Carbide Straight Blade Corner Angle End Mill, 2-Flute, with Chamfering Blade

- Long Shank Slotting End Mill SLEMLS

Customers Who Viewed This Item Also Viewed

-

Carbide Straight Blade Corner Angle End Mill, 2-Flute, Rounded Shoulder Type

Carbide Straight Blade Corner Angle End Mill, 2-Flute, Rounded Shoulder TypeMISUMI

Days to Ship : 5 Days

-

Carbide Straight Blade Corner Angle End Mill, 2-Flute, Back Tapered Type

Carbide Straight Blade Corner Angle End Mill, 2-Flute, Back Tapered TypeMISUMI

Days to Ship : 5 Days

-

Carbide Straight Blade Corner Angle End Mill, 2-Flute, Rounded Corner Type

Carbide Straight Blade Corner Angle End Mill, 2-Flute, Rounded Corner TypeMISUMI

Days to Ship : 5 Days

-

-

-

-

-

Carbide Straight Blade Corner Angle End Mill, 2-Flute, Rounded Inner Type

Carbide Straight Blade Corner Angle End Mill, 2-Flute, Rounded Inner TypeMISUMI

Days to Ship : 5 Days

-

Carbide Straight Blade Corner Angle End Mill, 2-Flute, with Chamfering Blade

Carbide Straight Blade Corner Angle End Mill, 2-Flute, with Chamfering BladeMISUMI

Days to Ship : 5 Days

-

-

-

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy