MenuClose

Carbide Solid Drill Bits - Straight/End Mill Shank, Flat Type, ADF-2D

[Features]

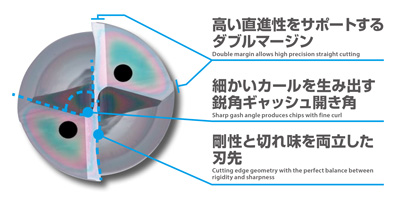

· Can be used in various applications such as counterboring of inclined and curved surfaces and semi-split hole drilling.

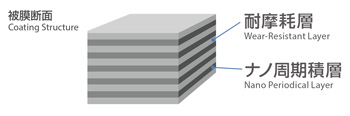

· The wear-resistant layer suppresses abrasion and prevents crack propagation due to the periodic nano-layered coating.

· The original bottom edge shape reduces the cutting resistance and achieves stable processing.

(i)Caution

- Unevenness in color may occur in the coating, but this does not affect the performance.

Part Number

Configure to get your Part Number

Carbide Flat Drill ADF Series

Basic specifications and features of the product

For various processing applications!

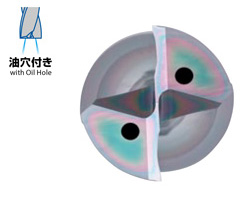

Introducing ADFO with oil holes for stainless steel! !!

Highly rigid 20° twist groove

ADF-2D/ADFLS-2D/ADFO-3D

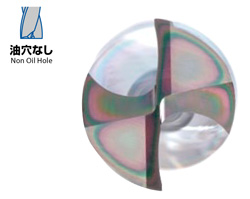

ADF-2D / ADFLS-2D

・General purpose

・Can process up to 2D

・Supports various processing applications

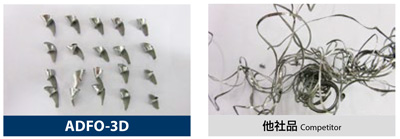

ADFO-3D

・Can process up to 3D

・Stainless steel can also be processed *

* Finely divide chips

Work Material: SUS304

This one can be used for various processing applications!

It can be used for various purposes such as counterboring on inclined surfaces and curved surfaces, and half crack hole processing.

■M6 or less Rolling tap Standard size compatible with pilot hole processing

It is not possible to make a radial cut.

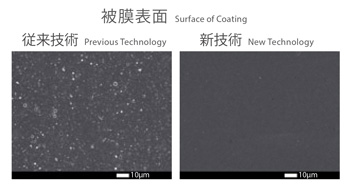

IchAda coating (less than φ2 ) that boasts excellent surface smoothness

In addition to high wear resistance and heat resistance, excellent smoothness extends the service life of small diameter tools.

IchAda is a registered trademark of OSG Corporation.

EgiAs coating with high wear resistance and toughness (φ2 or more)

Along with high wear resistance and heat resistance, a film with excellent toughness realizes long life and stable life.

| Name of coating | Coating color | Coating structure | Hardness (GPa) | Oxidation start temperature (℃) | Heat-resistant | Adhesion | Surface roughness | Wear resistance | Adhesion resistance | Toughness |

|---|---|---|---|---|---|---|---|---|---|---|

| IchAda | Black gray | Cr-based single layer | 39 | 1,100 | ◎ | ◎ | ☆ | ◎ | ◎ | ○ |

| EgiAs | Interference color | Cr,Si-based nano periodic stacking | 40 | 1,100 | ◎ | ◎ | ○ | ◎ | ◎ | ◎ |

(Standard) ○ → ◎ → ☆ (Optimal) EgiAs is a registered trademark of OSG Corporation.

Small diameter flat surface processing (no oil hole)

| Tools used | ADF-2D φ0.2 |

| Processing surface | Plane |

| Work material | SUS304 |

| Cutting speed | 25m/min (38,788min -1 ) |

| Feed rate | 58mm/min (0.0015mm/rev) |

| Hole depth | 0.4 mm (stop) |

| Cutting fluid | Water-soluble cutting fluid |

| Used machine | Vertical machining center (HSK E25) |

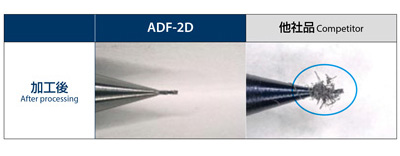

Comparison after processing 100 holes

Processing of inclined surface (no oil hole)

| Tools used | ADF-2D φ10 |

| Processing surface | Inclined surface (30°) |

| Work material | SCM440 (30HRC) |

| Cutting speed | 60m/min (1,910min -1 ) |

| Feed rate | 191mm/min (0.1mm/rev) |

| Hole depth | 20mm (stop) |

| Cutting fluid | Water-soluble cutting fluid |

| Used machine | Horizontal machining center (BT40) |

Amount of hole misalignment

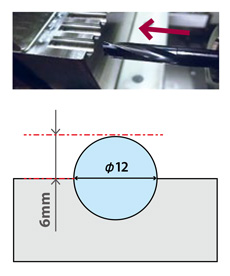

Machining of half cracked holes (no oil holes)

| Tools used | ADF-2D φ12 |

| Processing surface | Plane |

| Work material | S50C |

| Cutting speed | 37m/min (982min -1 ) |

| Feed rate | 157mm/min (0.16mm/rev) |

| Hole depth | 24mm (stop) |

| Cutting fluid | Water-soluble cutting fluid |

| Used machine | Horizontal machining center (BT40) |

Tilt amount (based on a value of 1 mm from the mouth)

Flat surface processing (no oil hole)

| Tools used | ADF-2D φ10 |

| Processing surface | Plane |

| Work material | S50C |

| Cutting speed | 75m/min (2,387min -1 ) |

| Feed rate | 430mm/min (0.18mm/rev) |

| Hole depth | 20mm (street) |

| Cutting fluid | Water-soluble cutting fluid |

| Used machine | Horizontal machining center (BT40) |

Hole expansion allowance

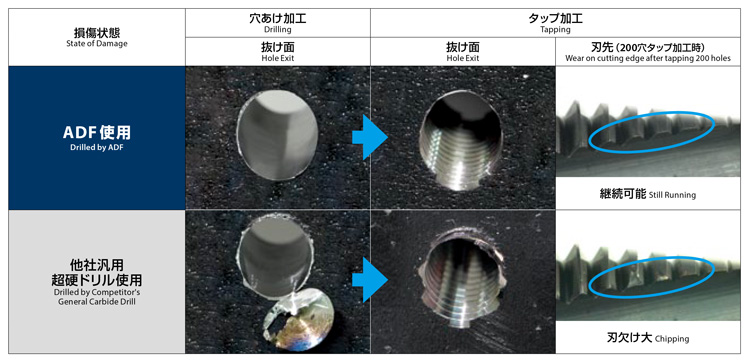

Pre-drilling of tap (no oil hole)

| Processing method | Drilling | Tap processing | |

| Tools used | ADF-2D φ8.5 | Competitor's general-purpose carbide drill | A-POT M10 x 1.5 |

| Processing surface | Plane → inclined surface (30°) | ||

| Work material | SS400 | ||

| Cutting speed | 50m/min (1,873min -1 ) | 30m/min (955min -1 ) | |

| Feed rate | 318mm/min (0.17mm/rev) | - | |

| Hole depth | 20mm (street) | ||

| Cutting fluid | Water-soluble cutting fluid | ||

| Used machine | Horizontal machining center (with synchronous feed mechanism) | ||

■Comparison of pull-out surface and cutting edge for each drill

If you use a general-purpose carbide drill made by another company, the burrs will be large and the tap durability will be unstable.

On the other hand, when processed with ADF, tap durability was stable.

Dimensions

Recommended cutting condition table

- For this cutting condition, the number of revolutions, feed rate and depth of cut are listed for each work material (general steel, alloy steel, tempered steel, high hardness steel, stainless steel, aluminum, cast iron, etc.) based on the manufacturer's recommended conditions. Thing.

- The optimum machining conditions vary depending on the machining environment (machine tool, tooling, etc.), so check the machining conditions (machining surface, chattering, etc.) before use.

AFD-2D

Precautions for cutting conditions

1. The table above is based on the assumption that the top surface of the work is flat and pre-milling has been performed, and that a water-soluble cutting fluid is used.2. When using water-insoluble cutting fluid or water-soluble cutting fluid that exceeds 20 times, reduce the cutting speed by 30%.

3. Use a machine and holder that are rigid and highly accurate.

4. When using, keep the tool protrusion amount to the necessary minimum.

5. Adjust the cutting conditions according to the shape of the work piece and the status of the holding method.

6. Keep the run-out of the cutting edge when installing the drill to 0.01 mm or less.

7. When machining on a slope, adjust the rotation speed and feed rate according to the machining surface inclination angle (β).

- When processing a slope with a processing surface inclination angle (β) of 30° or less, use the feed rate of 40 to 60% in the above table as a guide.

- When processing a slope with a processing surface inclination angle (β) exceeding 30°, use the rotation speed of 60 to 80% and the feed rate of 40 to 60% as a guide.

8. If there is a pilot hole, chips will not be divided, so perform step processing.

9. If the machining hole positioning accuracy is required, adjust the above rotation speed and feed rate according to the machining accuracy.

10. Please use the machine with φ5 or less on a machine with good spindle rotation accuracy.

11. If the machine speed does not meet the above cutting speed, use as high a speed as possible. In this case, durability may decrease.

Applicable work material

Low carbon steel/mild steel/alloy steel: (C<0.3%) SS400/SCMCarbon steel: S35C/S50C

Alloy steel: SCM/SCr/SNCM

Plastic mold steel: NAK80

Stainless steel: SUS304

special steel/ tempered steel/ Pre-hardened steel

Cast iron: FC250

Ductile cast iron: FCD600

Aluminum wrought material: A5052/A7075

Aluminum alloy casting: AC4C/ADC

Loading...

Basic Information

| Work material | General steel / Quenched and tempered steel / Cast Iron / Aluminum / Copper / Resin | Tool Material Type | Carbide | Coating Y/N | Available |

|---|---|---|---|---|---|

| Coating Type | Other | With/without Oil Hole | NA | Coating Details | EgiAs Coating |

-

Hole diameter (drill diameter) Dc(mm)

- 2

- 2.1

- 2.2

- 2.3

- 2.32

- 2.4

- 2.42

- 2.5

- 2.54

- 2.58

- 2.6

- 2.7

- 2.76

- 2.78

- 2.8

- 2.9

- 3

- 3.03

- 3.1

- 3.15

- 3.2

- 3.3

- 3.4

- 3.5

- 3.53

- 3.6

- 3.66

- 3.68

- 3.7

- 3.8

- 3.9

- 4

- 4.03

- 4.1

- 4.2

- 4.3

- 4.4

- 4.5

- 4.53

- 4.6

- 4.62

- 4.64

- 4.7

- 4.8

- 4.9

- 5

- 5.03

- 5.1

- 5.2

- 5.3

- 5.4

- 5.5

- 5.52

- 5.54

- 5.6

- 5.7

- 5.8

- 5.9

- 6

- 6.03

- 6.1

- 6.2

- 6.3

- 6.4

- 6.5

- 6.53

- 6.6

- 6.7

- 6.8

- 6.9

- 7

- 7.03

- 7.1

- 7.2

- 7.3

- 7.4

- 7.5

- 7.6

- 7.7

- 7.8

- 7.9

- 8

- 8.03

- 8.1

- 8.2

- 8.3

- 8.4

- 8.5

- 8.53

- 8.6

- 8.7

- 8.8

- 8.9

- 9

- 9.03

- 9.1

- 9.2

- 9.3

- 9.4

- 9.5

- 9.6

- 9.7

- 9.8

- 9.9

- 10

- 10.03

- 10.1

- 10.2

- 10.3

- 10.4

- 10.5

- 10.6

- 10.7

- 10.8

- 10.9

- 11

- 11.03

- 11.1

- 11.2

- 11.3

- 11.4

- 11.5

- 11.6

- 11.7

- 11.8

- 11.9

- 12

- 12.03

- 12.1

- 12.2

- 12.3

- 12.4

- 12.5

- 12.6

- 12.7

- 12.8

- 12.9

- 13

- 13.1

- 13.2

- 13.3

- 13.4

- 13.5

- 13.6

- 13.7

- 13.8

- 13.9

- 14.1

- 14.2

- 14.3

- 14.4

- 14.5

- 14.6

- 14.7

- 14.8

- 14.9

- 15.1

- 15.2

- 15.3

- 15.4

- 15.5

- 15.6

- 15.7

- 15.8

- 15.9

- 16

- 16.5

- 17

- 17.5

- 18

- 18.5

- 19

- 19.5

- 20

-

Groove Length L(mm)

-

Overall Length L(mm)

-

Shank Type

- End Mill Shank

- Straight shank

-

Shank Diameter(mm)

-

Tool No.

- 3330200

- 3330210

- 3330220

- 3330230

- 3330232

- 3330240

- 3330242

- 3330250

- 3330254

- 3330258

- 3330260

- 3330270

- 3330276

- 3330278

- 3330280

- 3330290

- 3330300

- 3330303

- 3330310

- 3330315

- 3330320

- 3330330

- 3330340

- 3330350

- 3330353

- 3330360

- 3330366

- 3330368

- 3330370

- 3330380

- 3330390

- 3330400

- 3330403

- 3330410

- 3330420

- 3330430

- 3330440

- 3330450

- 3330453

- 3330460

- 3330462

- 3330464

- 3330470

- 3330480

- 3330490

- 3330500

- 3330503

- 3330510

- 3330520

- 3330530

- 3330540

- 3330550

- 3330552

- 3330554

- 3330560

- 3330570

- 3330580

- 3330590

- 3330600

- 3330603

- 3330610

- 3330620

- 3330630

- 3330640

- 3330650

- 3330653

- 3330660

- 3330670

- 3330680

- 3330690

- 3330700

- 3330703

- 3330710

- 3330720

- 3330730

- 3330740

- 3330750

- 3330760

- 3330770

- 3330780

- 3330790

- 3330800

- 3330803

- 3330810

- 3330820

- 3330830

- 3330840

- 3330850

- 3330853

- 3330860

- 3330870

- 3330880

- 3330890

- 3330900

- 3330903

- 3330910

- 3330920

- 3330930

- 3330940

- 3330950

- 3330960

- 3330970

- 3330980

- 3330990

- 3331000

- 3331003

- 3331010

- 3331020

- 3331030

- 3331040

- 3331050

- 3331060

- 3331070

- 3331080

- 3331090

- 3331100

- 3331103

- 3331110

- 3331120

- 3331130

- 3331140

- 3331150

- 3331160

- 3331170

- 3331180

- 3331190

- 3331200

- 3331203

- 3331210

- 3331220

- 3331230

- 3331240

- 3331250

- 3331260

- 3331270

- 3331280

- 3331290

- 3331300

- 3331310

- 3331320

- 3331330

- 3331340

- 3331350

- 3331360

- 3331370

- 3331380

- 3331390

- 3331410

- 3331420

- 3331430

- 3331440

- 3331450

- 3331460

- 3331470

- 3331480

- 3331490

- 3331510

- 3331520

- 3331530

- 3331540

- 3331550

- 3331560

- 3331570

- 3331580

- 3331590

- 3331600

- 3331650

- 3331700

- 3331750

- 3331800

- 3331850

- 3331900

- 3331950

- 3332000

-

Under Head Length ℓ₂(mm)

-

type

- ADF-2D

Days to Ship

-

- All

- 4 Days or Less

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Additional Products in this Category

- Carbide Solid Drill Bits - Straight Shank, TiAlN Coated, Long

- Carbide Solid Drill Bits - End Mill Shank, Toglon Hard Bit, 20D, ALT Coated, Long

- Carbide Solid Drill Bits - Straight Shank, 200 mm, GT100 J683

- Carbide Solid Drill Bits - Straight Shank, 200 mm, GT100 J763

- Carbide Solid Drill Bits - Straight Shank, 100 mm, GT100 J711

- Carbide Solid Drill Bits - Straight/End Mill Shanks, for Cast Iron Machining, TOP-SLD

- Carbide Solid Drill Bits - End Mill Shank, Solid Pivot Type, KDR-DLC

- Carbide Solid Drill Bits - Union Tool Drill Bit, 1.6 X 10, UDCMX

Customers Who Viewed This Item Also Viewed

-

Carbide Solid Drill Bits - Aqua Drill EX Bit, for Counter Boring, AQDEXZ

Carbide Solid Drill Bits - Aqua Drill EX Bit, for Counter Boring, AQDEXZNachi-Fujikoshi

Days to Ship : 4 Days

-

-

-

-

-

-

-

-

Carbide Solid Drill Bits - Aqua Drill EX Bit, Flat Type, AQDEXZR, Regular

Carbide Solid Drill Bits - Aqua Drill EX Bit, Flat Type, AQDEXZR, RegularNachi-Fujikoshi

Days to Ship : 4 Days

-

-

-

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy